Our Maintenance Services

Since 2023, CEAR has integrated Rancan Elettrotecnica, a national benchmark for analysis, maintenance services, also with repair, and balancing for electric motors.

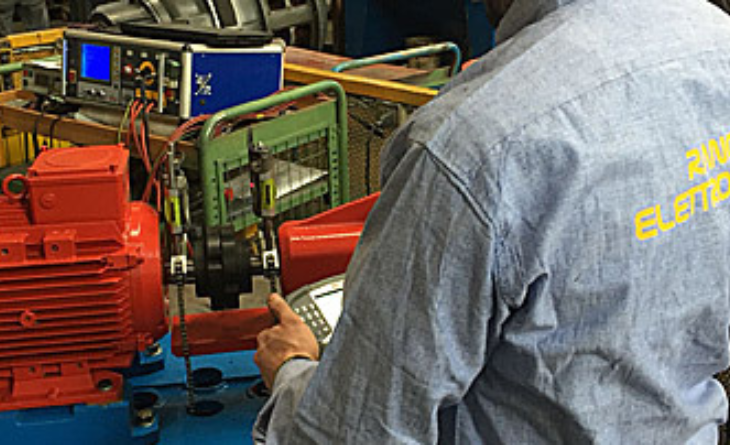

For our team, the repair of electric motors doesn’t start when we receive the machine, but when you call to inform us about an inefficiency to be eliminated. Therefore, the first step will be to ask you what the detected fault is and if it occurred under a particular operating condition. Such information is essential for performing maintenance services that can resolve the machine downtime and prevent its recurrence.

The same attention is then applied during the disassembly of the machine, especially during the electrical and mechanical inspections: our experience, translated into a series of specific tests for each type of machine, ensures that no aspect of the fault escapes analysis. The manner in which the fault occurs is indicative of its cause, providing precise indications on the measures to be adopted for guaranteed operation.

Often, for specific needs (humid environments, high-temperature environments, inverter power supply, etc.), the repair is adapted to equip the electric machine with the necessary electrical and mechanical measures that make it more reliable.

Instrumental predictive analysis, performed during functional restart, also uncovers other system inefficiencies that affect the proper functioning of the electric motor (imbalance of other rotating components, misalignment, resonant structure, power inverter malfunction, etc.).

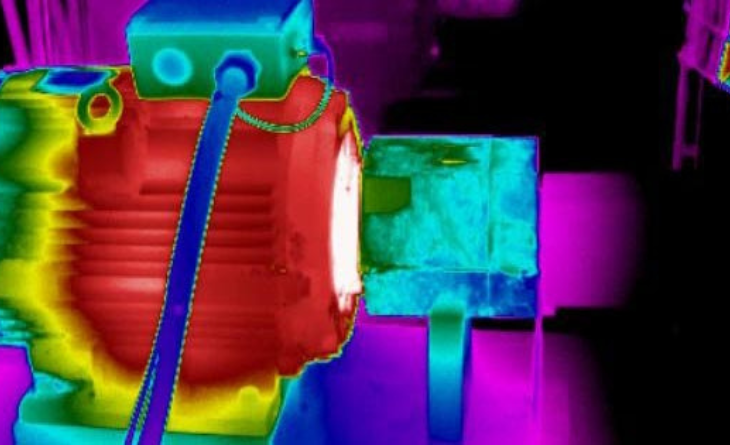

Thermographic Analysis

Thanks to predictive thermographic analysis, the risk of production stoppage

More Details

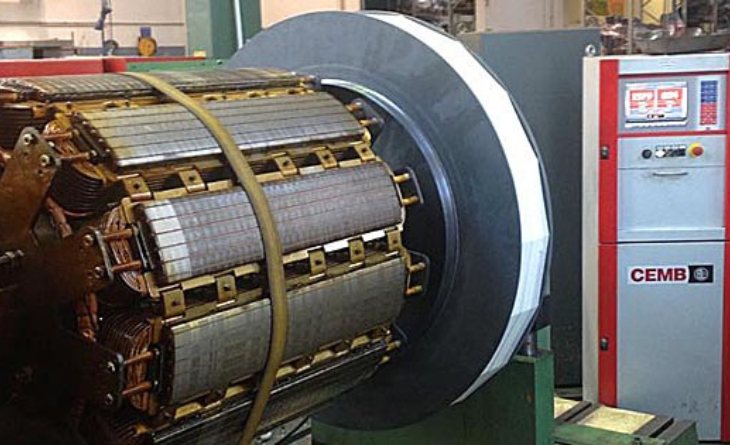

Balancing Rotating Machines

Most of the vehicles get damaged just because of maintenance

More Details

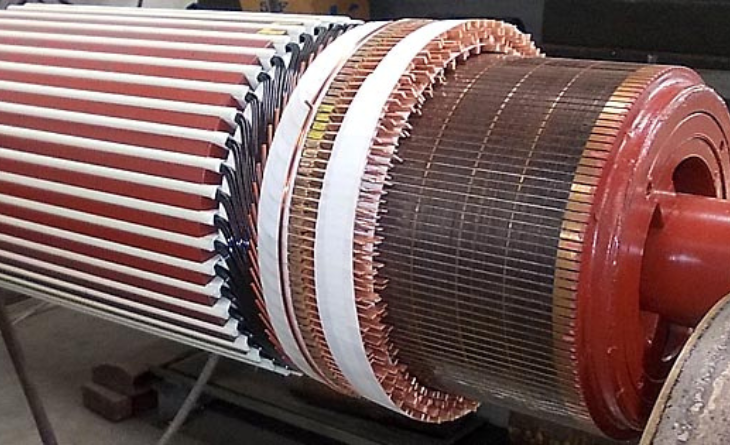

Electrical Windings

Execution of electrical windings for rotating machines, specific to type:

More Details

Machine Alignment

Thanks to machine alignment, we identify any shaft misalignments, minimizing

More Details

Fan Balancing

Bilanciatura ventilatori ed equilibratura: come eseguirla efficacemente risparmiando risorse.

More DetailsWork Phases

- Preliminary Electrical and Mechanical Inspection

- Complete Disassembly

- Cleaning and Inspection of All Mechanical Parts (bearing housing, commutator housing, etc.)

- Cleaning Windings through blowing and repeated washing with hot water and detergent

- Cleaning and Inspecting Brush Holders

- Drying in a Controlled Temperature Ventilated Oven

- Electrical Tests on Windings

- Dismantling and Rebuilding Rotor and Stator Windings (standard, for high operating temperatures, for motors powered by inverters or soft starters)

- Impregnation of Windings in Autoclave (vacuum technique)

- Drying Windings in a Controlled Temperature Ventilated Oven

- Tropicalization of Windings with insulating enamel

- Commutator and Ring Grinding

- Commutator Segmentation

- Rotor Balancing

- Supply of Spare Parts

- Remetalization of Worn Mechanical Parts (bearing housing, coupling housing, mechanical seal housing, etc.)

- Assembly of the Electric Machine

- Functional No-Load Testing (load testing at our customers’ premises for rotating electric machine manufacturers)

- Finishing

- Final Coloring

The Sectors We Work With

- Foundry, Steel, and Metal Forging Industry (steel, cast iron, aluminum, copper, etc.)

- Paper Industry

- Plastics Industry

- Cable and Electrical Wire Production Industry

- Chemical Industry

- Terracotta and Concrete Manufacturing Industry

- Building Materials Extraction and Processing Industry (marble, granite)

- Textile Industry

- Wood Industry

- Food Industry

- Printing Industry

- Packaging Industry

- Leather and Tanning Industry

- Industrial Plant Maintenance Companies

- Industrial Plant Installation Companies

- Electric Power Generation Plants

- Water Pumping Stations

- Water Treatment Plants

- Material and People Lifting Systems

Our extensive experience and diverse product range ensure that we can meet the needs of clients across these and many other industries.