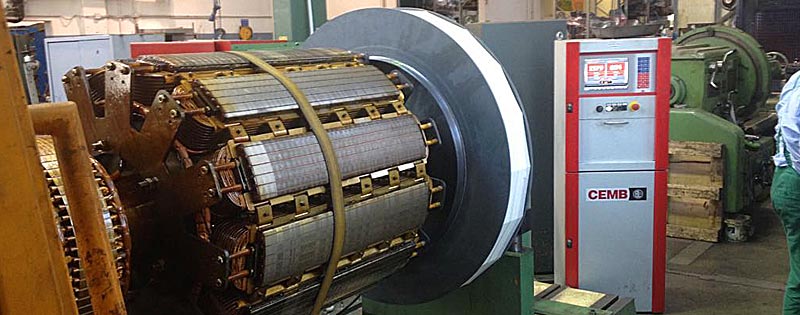

Balancing and Equilibrating Industrial Rotating Components

Precise balancing and equilibrating of fans, turbines, propellers, impellers, centrifuge cylinders, and rotary drums are achievable with the balancing machines we have at our disposal.

For over 20 years, we have specialized in balancing various types of industrial rotating devices on single or dual planes, using either static or dynamic balancing methods. Depending on functional requirements, the rotating component can be balanced by adding corrective weights or by material removal.

Our balancing machines’ software allows us to print a report that details the initial imbalance, the balancing speed expressed in revolutions per minute (RPM), the final imbalance, and the dimensional data set for configuring the rotating component.

When the system is put into operation, different support conditions for the rotating component may lead to residual vibrations. In such cases, we can intervene at the production site with suitable instrumentation. This allows us to first perform a vibration analysis and then carry out subsequent balancing of the rotating component in its operational environment.

Balancing and Equilibrating Industrial Rotating Components

Balancing industrial rotating components is crucial in all production sectors for several reasons:

-

Reduction of Vibrations:

- Unbalanced rotating components can generate undesirable vibrations. These vibrations can cause equipment damage, decrease operational efficiency, and lead to failures.

-

Increased Service Life:

- Proper balancing helps preserve the service life of rotating components. By reducing stress and strain, it prevents premature wear and breakages.

-

Improved Performance:

- Balanced components operate more efficiently. Reducing vibrations and stress leads to better precision in operations, which can be critical in many industries.

-

Safety:

- Vibrations and imbalances can compromise the safety of your plant. Accurate balancing reduces these risks and enhances overall production and working conditions.

-

Energy Savings:

- Balanced components require less energy to function properly, contributing to energy savings and reducing operational costs.