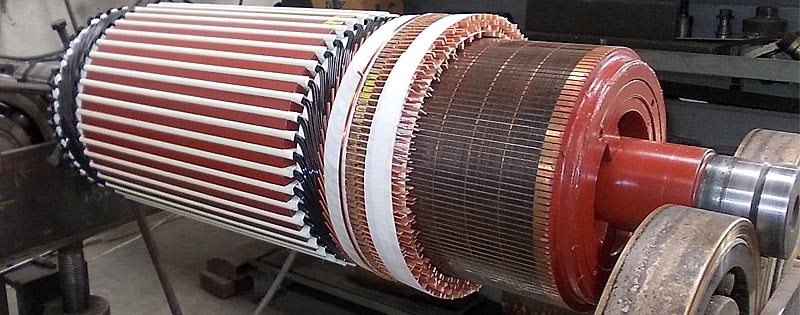

With years of experience in electric motor repairs, we execute windings on new electric machines with the necessary technical precautions for efficient and reliable long-term operation.

Our expertise addresses various challenges, such as:

- Drive and Inverter Use: Handling issues related to using drives and inverters as power supply devices for electric machines.

- High-Temperature Operation: Designing windings for machines that operate in high-temperature environments.

- Insulation Integrity: Ensuring insulation integrity in environments contaminated with humidity and conductive dust.

Custom Winding Solutions:

Materials:

- Copper Wire and Flat Copper: Utilizing high-quality copper materials for optimal conductivity and performance.

- Certified Insulating Materials: Employing insulating materials certified to appropriate thermal classes to ensure expected performance.

2. Insulation Techniques:

- Autoclave Impregnation: Using resin impregnation in an autoclave to protect windings from external contaminants and enhance durability.

Our windings are designed and executed with different insulating materials and methods to achieve the best functionality over time, ensuring your electric machines operate at their highest potential.