Electrical Safety: Prevention with Thermographic Analysis

Thermographic analysis is a valuable predictive tool that uses infrared technology to minimize the risk of production downtime due to electrical failures. By eliminating hot spots in your electrical systems, you also reduce the risk of fire.

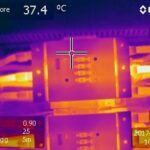

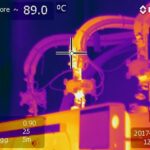

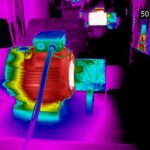

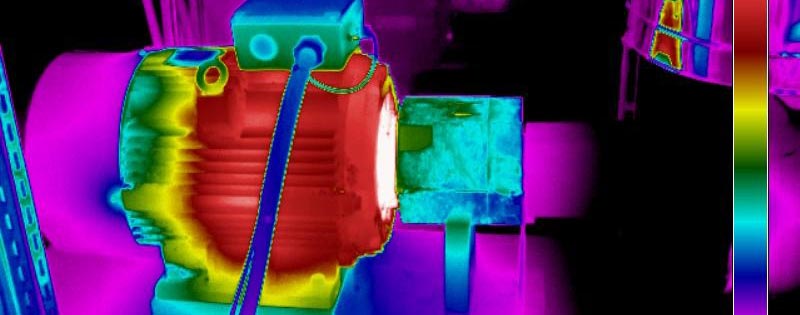

Thermographic analysis is the study of surface temperatures of industrial electrical/mechanical devices. It transforms infrared rays into a visible thermal image, allowing for the reading of temperatures at the hottest points.

Industrial thermography is the best tool for predictive and preventive monitoring of electrical systems. Through this type of industrial investigation, Rancan Elettrotecnica can diagnose potential issues such as:

- Short Circuits in Electrical Panels

- Current Overloads

- Load Imbalance on Three-Phase Systems

- Loose Fuse Contacts

- Loose Cable Connections

- Mechanical Malfunctions of Bearings or Gears

By detecting these issues early, thermographic analysis helps prevent unexpected failures and ensures the safe and efficient operation of your electrical systems.

Benefits of Thermographic Inspection

- Safety: Conducts inspections from a distance to eliminate the risk of electrical contact.

- Economic Savings: Thermal imaging identifies hot spots without shutting down equipment, minimizing operational disruptions.

- Time Savings in Maintenance: Instant thermographic analysis that quickly identifies devices that need repair or replacement, speeding up the maintenance process.

- Planned Corrective Action: Predictive alarms eliminates hot spots before they become critical risks.

- Economic Savings on Fire Insurance: Insurance benefits from lower premiums due to regular thermographic inspections.

- Historical Record of Hot Spots: Reports with thermal images that evaluates the effectiveness of interventions over time, providing a historical record of hot spots.

An effective application of thermographic analysis is the thermographic survey of medium voltage stations and substations in industrial plants. These surveys can detect temperature differences as small as a tenth of a degree. Even from a distance, they clearly highlight any looseness or imperfect contacts in the three-phase electrical supply lines.