Predictive Vibration Analysis

Vibration analysis can be performed as a predictive measure in investigating the wear status of rotating components in industrial plants. Only a thorough vibration analysis can identify which rotating components require maintenance in industrial plants: the subsequent maintenance interventions are targeted, optimizing resources and energy.

CEAR has the appropriate equipment to conduct vibration analysis investigations on industrial plants.

What is Vibration Analysis For?

The values obtained and the vibration spectra provide a precise functional picture of the electric machine, highlighting all current wear: from wear justified by the hours of operation to those that are already present anomalies (both mechanical and electrical). Vibrations of different frequencies objectively and unequivocally demonstrate the worn component.

Subsequent vibration analysis surveys, if performed periodically (semi-annually or annually), give a temporal prediction of the evolution of component wear, thus determining the maintenance shutdown times before a breakdown or failure occurs during production.

With this approach, interventions planned based on vibration analysis optimize costs by minimizing unexpected breakdowns and identifying precisely which components need maintenance or replacement, thus extending the life cycle of all components that still have guaranteed operating hours.

What Are the Results?

The valuable insights extrapolated from vibration analysis spectra define mechanical wear (worn bearings, loose supports, motor-to-driven machine misalignment, etc.) or electrical issues related to power supply (harmonics beyond permissible limits) or incorrect inverter supply connected to the driving motor.

Thus, there is no waste of resources on unnecessary or premature maintenance operations: the intervention allows for the timely replacement of worn components or recalibration of electrical parameters that are out of configuration.

We are not just a predictive analysis firm that provides an opinion on a problem, but a company that delivers field operations along with the solution: starting from a thorough preliminary analysis of existing vibrations, we define the operational plan. Upon completing the intervention, we proceed with further vibration analysis to verify the expected outcome.

Often, clients request our intervention to analyze excessive vibrations in a fan, even after having performed other balancing over time: our investigation method highlights the real causes of the imbalance that go beyond the fan’s inherent imbalance. This results in a conclusive intervention with immediate feedback on the results obtained.

A Practical Case

In a steel mill, an abnormal operating noise was reported in the silo loading crane lifting group.

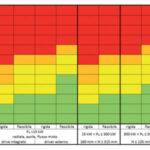

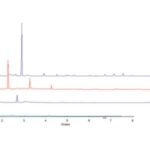

After conducting a vibration survey on both lifting motors and the central gearbox, we analyzed the overall vibration spectra at various frequencies to identify all peaks related to gear mesh pairs (gears in engagement), specifically detecting one with an absolute value higher than the average of the others.

Using the typical mechanical data of the gears, it is possible, through vibration analysis, to identify if there is a specific vibration for each gear pair and determine if there is any exceedance of permissible limits.

In the described case, it was the second reduction pair within the gearbox that showed greater wear than the other pairs, though no gear breakage was evident. With ample advance notice before a failure and consequent production stoppage, the vibration analysis allowed for the planning of the gearbox maintenance intervention without disrupting normal production.

There was no attempt at unnecessary correction or adjustment, but rather an intervention that involved minimal resource and financial commitment, limited to the components needing care or replacement. Vibration analysis allows for intervention before a failure occurs, reducing both maintenance costs and production downtime.